Baking

Deck oven

Deck ovens use conduction heat to bake products. Conduction heating is a process in which heat travels directly from a hot stone or deck, to the loaf of bread or sheet pan being baked. Deck ovens also utilize radiant heat, which is a process that utilizes infrared heat waves to penetrate into the dough, heating it throughout.

The ability to add steam with these types of ovens is also key in the bread baking process, and because deck ovens carry so much mass they have great recovery time and hold temperature very well.

ELEOVEN-1D

- Voltage220 V, 1-phase

- Power7 kW

- Dimension1210*810*520 mm

- Net weight80 Kg

- Specification1 deck, 2 trays 60*40 cm

ELEOVEN-2D

- Voltage380 V, 3-phase

- Power14 kW

- Dimension1210*810*1280 mm

- Net weight170 Kg

- Specification2 decks, 4 trays 60*40 cm

ELEOVEN-P16

- Voltage380 V, 3-phase

- Power6.7 kW

- Dimension910*1080*430 mm

- Inner dimension 600*900*150 mm

- Temperature range200-380 C

GASOVEN-1D

- Voltage220 V, 1-phase

- Power0.1 kW

- Dimension1330*895*690 mm

- Net weight139 Kg

- Specification1 deck, 2 trays 60*40 cm

GASOVEN-2D

- Voltage220 V, 1-phase

- Power0.2 kW

- Dimension1330*895*1400 mm

- Net weight250 Kg

- Specification2 decks, 4 trays 60*40 cm

Horizontal mixer

The short sections called "paddles" or "ploughs" are spaced in a spiral round the mixer shaft. Suitable for mixing liquids with dry solids.

These mixers usually have a higher consistent homogeneity and short mixing times.

HORMIX15

- Voltage220 V, 1-phase

- Power1.5 kW

- Dimension680*400*800 mm

- Net weight75 Kg

- Capacity30 L

- Speed30 rpm

- Max kneading15 Kg

HORMIX25

- Voltage220 V, 1-phase

- Power1.5 kW

- Dimension790*460*860 mm

- Net weight90 Kg

- Capacity50 L

- Speed30 rpm

- Max kneading25 Kg

HORMIX50

- Voltage380 V, 3-phase

- Power2.2 kW

- Dimension1000*580*1050 mm

- Net weight130 Kg

- Capacity100 L

- Speed30 rpm

- Max kneading50 Kg

Planetary mixer

In most pastry shop or bakery you will find at least one planetary mixer. The reason these mixers are so common is that they offer greater versatility. The paddle attachment is used for blending or creaming products. The whip attachment is commonly used to aerate mixtures, and lastly, the dough hook attachment is used to make doughs.

Standard attachments include a paddle, a whip, and a dough hook. These machines also come with 3 speed options to accommodate different mixing needs.

PLMIX10

- Voltage220 V, 1-phase

- Power0.6 kW

- Dimension440*390*710 mm

- Net weight61 Kg

- Speed148/ 244/ 480 rpm

- Capacity10 L

PLMIX20

- Voltage220 V, 1-phase

- Power0.75 kW

- Dimension540*415*763 mm

- Net weight82 Kg

- Speed94/ 165/ 386 rpm

- Capacity20 L

PLMIX30

- Voltage220 V, 1-phase

- Power1.1 kW

- Dimension590*435*830 mm

- Net weight90 Kg

- Speed94/ 165/ 386 rpm

- Capacity30 L

PLMIX7

- Voltage220 V, 1-phase

- Power0.35 kW

- Dimension480*300*500 mm

- Net weight30 Kg

Spiral mixer

The main function of the spiral mixer is to gently mix bread dough, allowing it to develop the proper gluten structure, while not overworking the dough. This is achieved because the bowl of the mixer rotates as the spiral hook is spinning and kneading the dough.

This spiral mixer also comes with 2 variable speeds, which facilitates dough development.

Most commonly used for mixing bread dough, spiral mixers are capable of handling a variety of different dough types. This includes very stiff dough with low hydration levels; and high hydration dough types such as ciabatta.

SPMIX20

- Voltage220 V, 1-phase

- Power1.5 kW

- Dimension730*390*900 mm

- Net weight90 Kg

- Speed112/ 198 rpm

- Bowl volume20 L

- Max kneading8 Kg

SPMIX40

- Voltage220 V, 1-phase

- Power1.5 kW

- Dimension840*480*1000 mm

- Net weight155 Kg

- Speed112/ 198 rpm

- Bowl volume40 L

- Max kneading16 Kg

SPMIX60

- Voltage220 V, 1-phase

- Power3 kW

- Dimension840*480*1000 mm

- Net weight180 Kg

- Speed112/ 198 rpm

- Bowl volume60 L

- Max kneading25 Kg

SPMIX80

- Voltage380 V, 3-phase

- Power3 kW

- Dimension1000*560*1380 mm

- Net weight300 Kg

- Speed100/ 200 rpm

- Bowl volume80 L

- Max kneading32 Kg

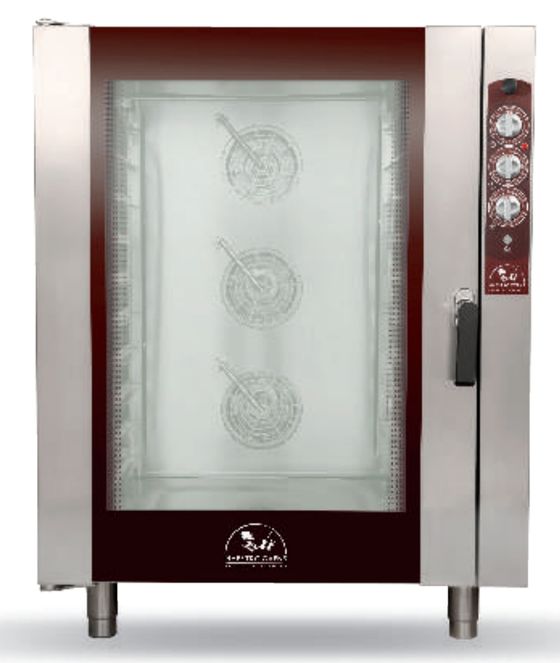

Convection oven

A versatile oven which operates by transferring heat through hot air blown from a fan.

One advantage of convection heating is that the products being baked will be heated evenly throughout. Also, you are able to bake products with a great range of temperature.

Another feature is the ability to add steam during baking. Adding steam allows rolls to get a nice shine and for breads to fully expand during baking.

For a majority of bakeries or pastry shops, having a convection oven that allows for versatility and uniform baking is paramount to their success.

Our gas convection ovens come from Maestro Ovens of Egypt. Their 30+ years of experience are a testament to their quality and exacting standards when it comes to ovens.

GASCOVEN-10TE

- Voltage220 V, 1-phase

- Power0.5 kW

- Dimension865*830*1450 mm

- Net weight200 Kg

- Capacity10 trays 60*40 cm

- Temperature range50-280 C

- Timer120 min

- FeaturesElectromechanical control knobs; Steam regulator

GASCOVEN-6TE

- Voltage220 V, 1-phase

- Power0.5 kW

- Dimension865*830*1010 mm

- Net weight165 Kg

- Capacity6 trays 60*40 cm

- Temperature range50-280 C

- Timer120 min

- FeaturesElectromechanical control knobs; Steam regulator

Let's expand your business

Partner with us to improve your production speed and efficiency. We cater equally to SMEs and large corporations.